|

Ayesha Automation and Equipment SupplierWebsite: https://ayeshaautomation.com |

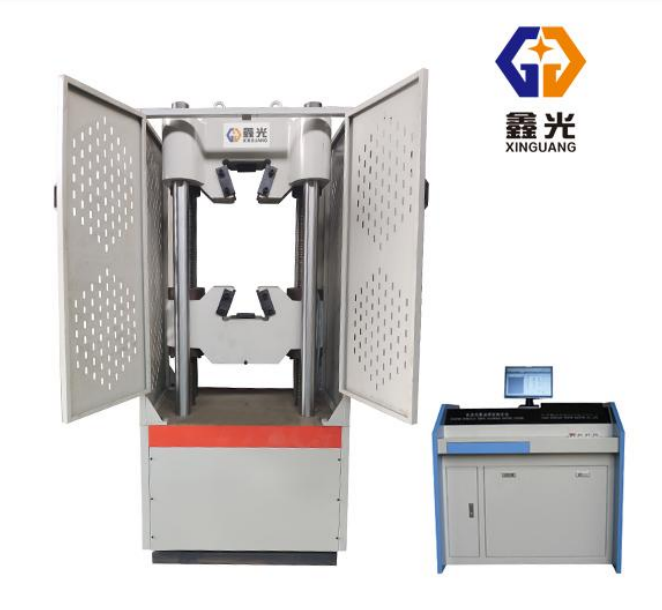

1000KN Electronic Universal Testing Machine with front Loading jaw

Features

| Brand | Xinguang |

| Origin | China |

| Category | Universal Testing Machine |

| Price |

BDT 3,250,000.00 BDT 3,290,000.00

|

Short Description

Model: WAW-1000D

Features:

- Hydraulic clamp for tension test, wedge clamp auto-lock by loading, round and flat grip changeable for different samples;

- Host machine adopt oil cylinder on bottom type structure, hydraulic load, hydraulic clamping specimen, tensile jaws fixed on cross beam, easily controlling of install and release sample;

- Adopt servo motor driver oil pump, with fast response, low noise, low temperature, safe and reliable;

- Micron level clearance sealing instead of O-ring sealing, loading stable and maintenance-free;

- Computer 3 close-loop Control testing mode of load, displacement and extension;

- Speed control from 5 to 50mm/min by servo motor;

- Remote controller adjusts the machine Crosshead before test and operate the Test conveniently;

- Support different Version of Microsoft windows OS of Windows 7/8/10

- Can be Connected to the information Network system of the enterprise or laboratory

- The controller is external type and can Connected to the computer with USB

Specifications

Brand: XINGUANG

Model: WAW-1000D

Technical Specification

- Computer Control Servo Hydraulic Universal Testing Machine is widely used for tension, compression, bending and shearing test of metal materials and also used for compression and bending test of nonmetal materials, such as cement, concrete and so on.

- Equipped with simple accessary, it will be used for mechanical property testing of fastener, wire rope and

- They are perfect testing instrument project quality testing section, universities and colleges, research institution and industrial and mining enterprise.

- The machine is calibrated according to ASTM E4 and ISO7500-1

- It can do many different kinds of test according to ISO6892, ISO7438, ASTM A370, ASTM E8 and BS EN

Features:

- Hydraulic clamp for tension test, wedge clamp auto-lock by loading, round and flat grip changeable for different samples;

- Host machine adopt oil cylinder on bottom type structure, hydraulic load, hydraulic clamping specimen, tensile jaws fixed on cross beam, easily controlling of install and release sample;

- Adopt servo motor driver oil pump, with fast response, low noise, low temperature, safe and reliable;

- Micron level clearance sealing instead of O-ring sealing, loading stable and maintenance-free;

- Computer 3 close-loop Control testing mode of load, displacement and extension;

- Speed control from 5 to 50mm/min by servo motor;

- Remote controller adjusts the machine Crosshead before test and operate the Test conveniently;

- Support different Version of Microsoft windows OS of Windows 7/8/10

- Can be Connected to the information Network system of the enterprise or laboratory

- The controller is external type and can Connected to the computer with USB

Application Software:

- N, KN, lbf, gf, kgf can be converted at will Test process, result display, result analysis, result print, all the function can be controlled by the computer, testing data and curve can real-time display during test;

- Computer 3 close-loop control testing mode of load, deformation displacement

- Various testing curves, Load-Time, Extension-Time, Stress-Strain, Load Extension, can zoom and analysis at Any point in the curve;

- Automatically calculate tensile strength, yield strength, modulus of elasticity, 2, Rt0.5;

- Support to change Excel format report, easy to pinpoint the location of the data;

- The same group sample can continuous testing, and can be analyzed separately for each test results;

- Can store testing result, testing curve and Data;

- Have “Stop while destroy” function, can automatic stop working when specimen is broken;

Technical Specification:

- Maximum force: Min 1000KN

- Measuring range of force: 2%-100% of load capacity or better

- Accuracy: ±1% of indicated value or better

- Resolution of displacement measure: 01mm or better

- Range of displacement speed: 5mm/min-50mm/min

- Clamping diameter of round specimen: φ 13-60mm

- Clamping thickness of flat specimen: 0-40mm

- Clamping width of flat specimen: 80-90 mm

- Valid tension space: 700mm or higher

- Valid compression space: 600mm or higher

- Compression plate size: 200mm*200mm (Min)

- Distance of bending by pass roll: 30-450mm

- Maximum piston stroke: 250mm

- Valid width between columns: min 500mm

- Power supply: 3P, 380V or 220V, 50/60Hz

- Working condition: RT10℃~30℃, relative humidity ≤ 80%

- Net weight: Min 2800 Kg

Following accessories should be included with System as standard:

- Servo motor

- Oil pressure sensor

- Oil pump & oil valves

- Controller

- Remote control box

- The test software

- Encoder

- Tools

- Operating computer system (Processor Core i7 12700, 12th/13th/14th Generation Supported Motherboard, 2.10GHz-4.90GHz, 215 GB SSD, 8GB RAM DDR4)

- Colour Laser Printer

- Wedge tension jaw

- Compress plates

- 4-position electric tool post

- 3-jaw chuck, chip tray and tailstock

- Tools (each 2 sets): Inner and outer threading tool, Inner and Outer Turning tool, Slotting / Parting tool

- Required Lubricant as per machine’s tank, cutting oil (Min. 3 liter) and required hydraulic oil as per machine’s capacity

- Half cover, inverter spindle and printed operation manual

- Analogue Cum Digital Rebound Hammer-01

- Country of Manufacture: China

Description

Technical Specification

- Computer Control Servo Hydraulic Universal Testing Machine is widely used for tension, compression, bending and shearing test of metal materials and also used for compression and bending test of nonmetal materials, such as cement, concrete and so on.

- Equipped with simple accessary, it will be used for mechanical property testing of fastener, wire rope and

- They are perfect testing instrument project quality testing section, universities and colleges, research institution and industrial and mining enterprise.

- The machine is calibrated according to ASTM E4 and ISO7500-1

- It can do many different kinds of test according to ISO6892, ISO7438, ASTM A370, ASTM E8 and BS EN

Features:

- Hydraulic clamp for tension test, wedge clamp auto-lock by loading, round and flat grip changeable for different samples;

- Host machine adopt oil cylinder on bottom type structure, hydraulic load, hydraulic clamping specimen, tensile jaws fixed on cross beam, easily controlling of install and release sample;

- Adopt servo motor driver oil pump, with fast response, low noise, low temperature, safe and reliable;

- Micron level clearance sealing instead of O-ring sealing, loading stable and maintenance-free;

- Computer 3 close-loop Control testing mode of load, displacement and extension;

- Speed control from 5 to 50mm/min by servo motor;

- Remote controller adjusts the machine Crosshead before test and operate the Test conveniently;

- Support different Version of Microsoft windows OS of Windows 7/8/10

- Can be Connected to the information Network system of the enterprise or laboratory

- The controller is external type and can Connected to the computer with USB

Application Software:

- N, KN, lbf, gf, kgf can be converted at will Test process, result display, result analysis, result print, all the function can be controlled by the computer, testing data and curve can real-time display during test;

- Computer 3 close-loop control testing mode of load, deformation displacement

- Various testing curves, Load-Time, Extension-Time, Stress-Strain, Load Extension, can zoom and analysis at Any point in the curve;

- Automatically calculate tensile strength, yield strength, modulus of elasticity, 2, Rt0.5;

- Support to change Excel format report, easy to pinpoint the location of the data;

- The same group sample can continuous testing, and can be analyzed separately for each test results;

- Can store testing result, testing curve and Data;

- Have “Stop while destroy” function, can automatic stop working when specimen is broken;

+880171

4670905,

aaes2062@

gmail.com